IMTS 2018: Cecor’s Sump Shark for machine tool sump cleaning helps maintain machine tool coolant by filtering dirty coolant and making the cleaning process faster and easier. #metalworkingfluids

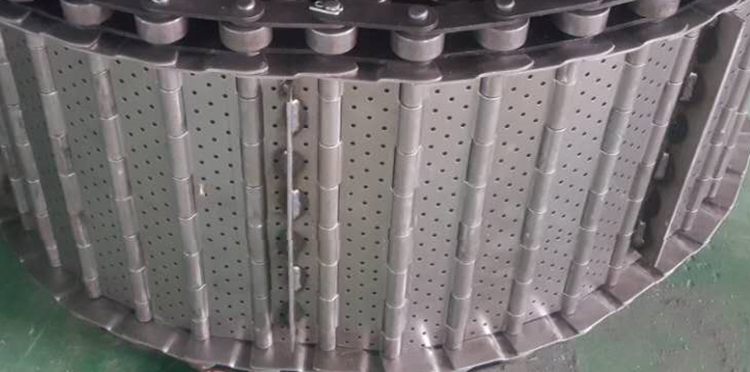

Cecor will feature its SE15 single-phase electric and SA5 air-operated Sump Shark units, which are designed to quickly and easily filter dirty coolant. With suction lifts ranging to 26" Hg (the pressure of 350" water), the units can clean sludge and metal chips from the entire sump of metalworking fluid in just minutes or seconds, depending on sump size, the company says. The solids are caught in the onboard filter as the coolant passes into the tank. The pump filters coolant out of the tank through the discharge-port hose. Cnc Machine Center Chip Conveyor

According to the company, the cleaning units are easier to use than a pail and a shovel, a shop vac or a diaphragm pump, thus decreasing labor costs and machine tool downtime. Additionally, the cleaning units increase coolant life and reduce waste.

The SE15 can be plugged into any 110-V electric unit. The SA5 operates on shop air. Each has overfill protection with valved discharge ports. They feature hoses, quick-disconnect couplers, suction tools and filter bags. An F23 filter (2.3 ft3) is available for coolant heavy with chips and swarf. A DF4 discharge filter is available for second-stage, very-fine filtering.

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

This technology offers an alternative to traditional liquid coolants by providing a clean stream of air as cold as -30°F to cool cutters and workpieces during machining.

Chain Conveyor Sometimes synthetic metalworking fluids end up negatively impacting tool life when used with tough materials. Wells Manufacturing overcame that issue when it converted to a new product from Blaser Swisslube.