Article from Persistence Market Research

A new market study, titled, "Diamond Tools Market: Global Industry Analysis 2013–2017 and Forecast 2018–2028," studies the global diamond tools market and offers deep-dive analysis for the next 10 years. The report on the global diamond tools market estimates the key macroeconomic and forecast factors that are projected to drive the growth of the diamond tools market. Squaring Wheel For Ancora

The diamond tools market is expected to grow at a CAGR of around 8.0% between 2018 and 2028, and is estimated to reach a global value of more than US$ 22,000 Mn by the end of 2028.

Diamond Tools Market: Segmental Analysis

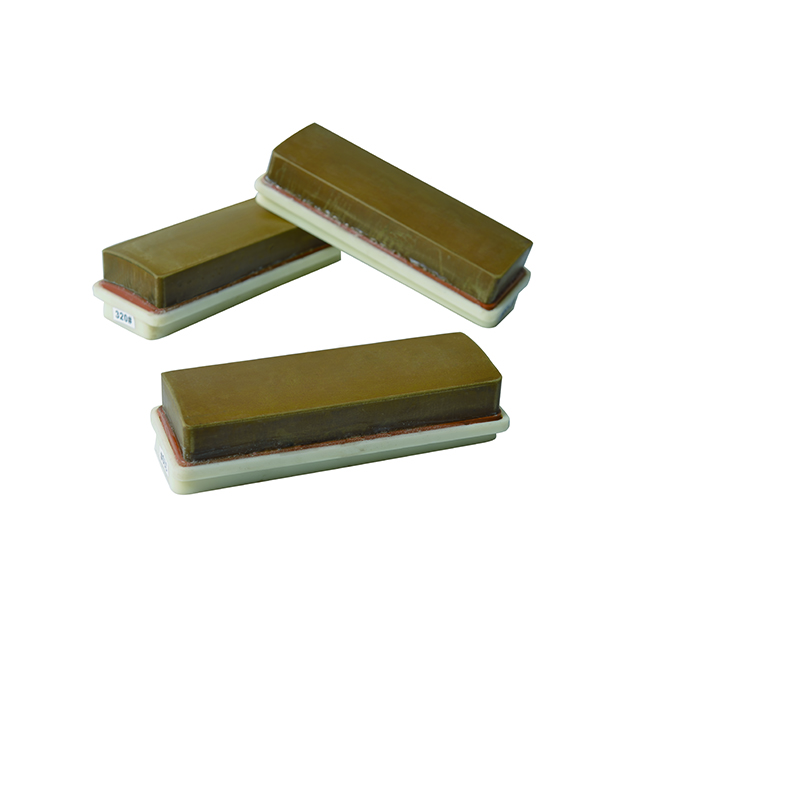

By tool type, the global diamond tools market is segmented as abrasive type (finishing-based and lapping-based), drilling tools, cutting tools, sawing tools, milling tools, diamond dressers, diamond gauging fingers and files. Among these segments, the abrasive type and milling tools segments are projected to grow at sizable value shares in the global market, owing to the rising demand for these tools from end-use industries.

By manufacturing method, the global diamond tools market is segmented into metal-bonded, resin-bonded and electroplated. The metal-bonded segment is expected to grow at a prominent rate in the global diamond tools market over the slated time period, owing to its increasing application in floor finishing. However, the electroplated segment is also expected to represent significant opportunity for the diamond tools market, owing to the rising application of electroplated diamond tools for machining material that cannot be economically ground with metal- or resin-bonded diamond tools.

By end use, the global diamond tools market is segmented into automotive, construction (glass, stone and ceramic), fabrication and general manufacturing, health care and pharmaceuticals, and aerospace and defense. Among these segments, the construction, automotive and aerospace and defense segments are estimated to grow at noteworthy rates in the global diamond tools market over the forecast period. In the automotive sector, diamond tools are used to make internal engine galleries and engine block holes, among other. Therefore, increasing automotive vehicle production across the world is projected to surge the demand for diamond tools in the next couple of years.

While, for aerospace, diamond tools are used to make wing tips, ducts and floor posts, among others, with CNC machines. Thus, for the safety and security of their nations, governments are outlaying significant money from their budgets in order to invest in R&D, which, in turn, is expected to boost the demand for diamond tools in the coming years. Moreover, diamond tools are also used in the health care industry to make accurate and lightweight medical equipment such as scissors and diamond-plated wheels. As such, growth in these above mentioned industries is collectively expected to accelerate the sales of diamond tools across the globe over the stipulated time period.

By region, the global diamond tools study has been completed in six regions: North America, Latin America, Europe, South Asia, East Asia, and the Middle East and Africa. The diamond tools market is directly dependent on the performance of the construction, stone processing, automotive, aerospace and health care industries in respective regions. According to a deep dive study, the markets in Europe, Latin America, South Asia and North America are projected to grow at significant growth rates in the global diamond tools market, as well as also account for healthy shares in the global diamond tools market.

The intensity of competition in the diamond tools market is low to medium. There are numerous players in the global market, which makes this market fragmented. However, 35%-40% of the market is held by Tier-1 players. In addition, leading companies in the diamond tools market are focused on increasing the number of their sales offices, as well as manufacturing plants, in a bid to gain a significant foothold in the global diamond tools market.

Some of the key players active in the global diamond tools market are Kyocera Unimerco A/S, Dellas SpA, Shinhan Diamond, Sumitomo Electric Industries Ltd., Texas Diamond Tools Inc., Hilti Group, Alpha Diamond Tools Co. Ltd., Shijiazhuang Kitsibo Tools Co. Ltd., Sanwa Diamond Tools, Hunan Qiliang Abrasive Tools Co. Ltd., Danyang Tianyi Diamond Tools Co. Ltd., Fujian Quanzhou Jinli Diamond Cutting Tools Co. Ltd., Monte-Bianco Diamond Applications Co. Ltd., Compagnie de Saint-Gobain SA, Syntec Diamond Tools Inc., Bell Impex (Juhai), G&G Surface Technology, Quanzhou JDK Diamond Tools Co. Ltd., Fujian Wanlong Group (Hong Kong) Co Ltd., Quanzhou Huangchang Diamond Tools Co. Ltd., Foshan Boer Ceramic Technique Co. Ltd., Quanzhou Jinshan Stone Tools, Quanzhou Tianli Grinding Tools Co. Ltd., Husqvarna AB, Tyrolit Schleifmittelwerke Swarovski KG, EHWA Diamond Industrial Co. Ltd., and Toolgal Industrial Diamonds Ltd.

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

Ceramic Diamond Calibrating Roller © Copyright 1995 - 2023. Cutting Tool Engineering. All rights reserved.