Germany — For some years now, it has been possible to manufacture metal components using fused layer modeling (FLM). Its limitations and quality characteristics compared to metal injection molding have now been explored by researchers at Fraunhofer IPA.

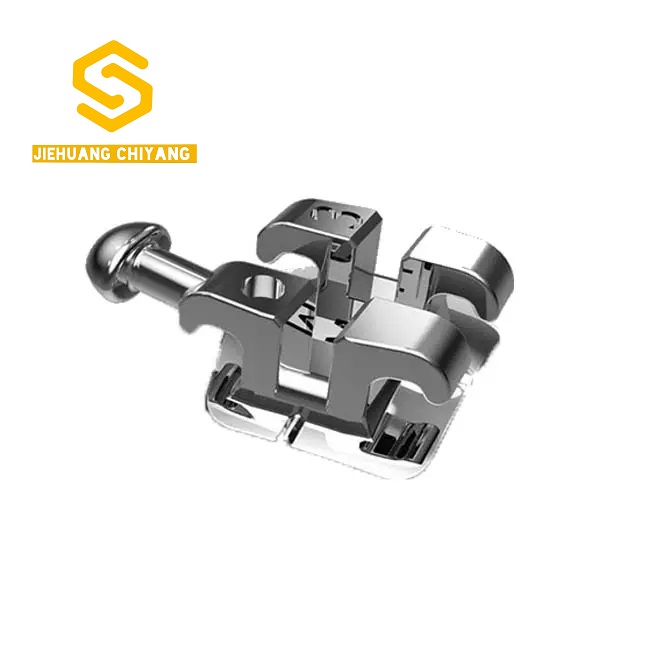

Metal Injection Molding (MIM) is mainly used in the automotive industry and by medical technology manufacturers and is tailored to high-volume production. Each component requires a corresponding mold, which is expensive and time-consuming to produce. The result of metal powder injection molding is a so-called green body, a preliminary product with slightly oversized dimensions, which then shrinks to the desired dimensions in the downstream debinding and sintering process. However, the MIM process is uneconomical for the production of small batches and individual parts. Powder Metallurgy Sintered Metal Parts

Researchers from the Center for Additive Production at Fraunhofer IPA, together with ML3D GmbH, have therefore produced and investigated stainless steel components using fused layer modeling (FLM). In the FLM process, the green body is produced from a mixture of metal powder and polymer binder using a low-cost 3D printer. The plastic component is removed during subsequent debinding. Only in the sintering furnace do the last polymer residues evaporate and the remaining metal powder particles are sintered.

The examination of the FLM metal component showed:

Manageable costs, non-hazardous handling of the material and relatively simple process: the FLM method has great potential for economic use compared to other 3D printing methods. ML3D GmbH wants to implement the findings from the joint project with Fraunhofer IPA and introduce the FLM process.

This article was first published on mission additive

Desktop Metal and the Kitech Partner to Promote Metal Binder Jetting in South Korea

The On Demand Manufacturing unit of 3D Systems becomes Quickparts

Imprint Cookie-Manager About Media Privacy General Terms and Conditions Help

Copyright © 2023 Vogel Communications Group

Mim Sintered Powder Metallurgy Parts This portal is a brand of Vogel Communications Group. You will find our complete range of products and services on www.vogel.com