Get Morning Report and other email newsletters

Get Morning Report and other email newsletters One Layer Flexible PCB

Just over one year ago, President Biden signed the CHIPS and Science Act, and a new era of American high-tech manufacturing was born.

Propelled by a strategic investment of tens of billions of dollars, the United States will construct a new semiconductor ecosystem here in the United States. The goal is twofold: to ensure that the chips that power American life will be there when we need them, and that the United States remains a leader in not only designing but making high-end microchips.

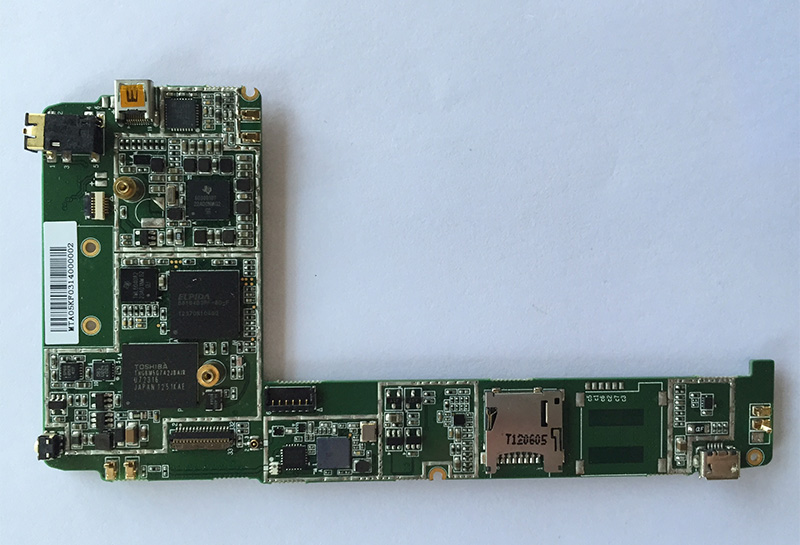

The CHIPS bill was a milestone, but the legislation failed to cover printed circuit boards, or PCBs, the complex structures on which chips sit. Often comprising dozens of layers, PCBs connect individual chips and enable larger systems and subsystems. They are essential: without PCBs, microchips would be nothing more than expensive silicon wafers.

The United States once boasted a robust PCB capacity that ensured that important systems from defense to mass transit to communications could source U.S.-made microelectronics. America used to make one in four of the world’s PCBs. Today, that number is down to one in 25.

From both an economic and national-security standpoint, it makes little sense to mount American-made chips onto foreign-made PCBs. It makes even less sense to send the chips overseas only to have them re-exported to the United States.

As our need for PCBs grows, we must make more of them here in America. Here in California, Sanmina, one of the nation’s largest remaining manufacturers of PCBs, operates a 100,000 square-foot facility in Costa Mesa that produces boards that enable everything from strategic communications equipment to fighter jets.

Make no mistake: PCBs will always rely on a global supply chain. There is no reason that electric toothbrushes and toasters cannot use PCBs made overseas. But we have become too dependent on foreign nations for the PCBs that power the electronics that run our critical infrastructure and sensitive national defense systems.

Congress can level the playing field for American PCB manufacturers by passing H.R. 3249, the Protecting Circuit Boards and Substrates (PCBS) Act. The PCBS Act calls for a 25% tax credit for companies buying American-made PCBs and a $3 billion investment in research and development, physical plant and workforce development.

Ensuring that the systems we rely on most are built using American PCBs is also a national security imperative. PCBs can be tampered with by an adversary, thus undermining a crucial CHIPS program goal: ensuring that the things that are most important to us run on American hardware.

Related Articles Commentary | Opinion: What kind of seafood is morally ethical to eat? Commentary | Opinion: Maybe Oakland Mayor Thao should ask for the National Guard Commentary | Opinion: The Palestinian and Jewish experiences are both valid Commentary | Opinion: Tijuana River sewage crisis leaves San Diegans helpless Commentary | Opinion: Santa Clara County leads locally on climate change Bringing more PCB manufacturing back to the United States will generate thousands of jobs — high-paying skilled work that does not require an engineering degree and in a growing industry.

Investing in America’s semiconductor supply chain was a triumph for a portion of the microelectronics ecosystem. We now need to finish the job by supporting the PCBS Act and investing in the entire ecosystem to create a trusted and resilient supply chain for the microelectronics that power our most critical national systems.

Eda Pcb Design Hari Pillai is president of the technology components group for San Jose-based Sanmina Corp. Travis Kelly is chairman of the Printed Circuit Board Association of America.