In early April 2023, the first slurry-type shaft boring machine (CREC 1206), designed and manufactured by China Railway Engineering Equipment Group Co., Ltd. (CREG), successfully completed the excavation of two blind shafts, innovating a new mode for the mechanized construction of pump room.

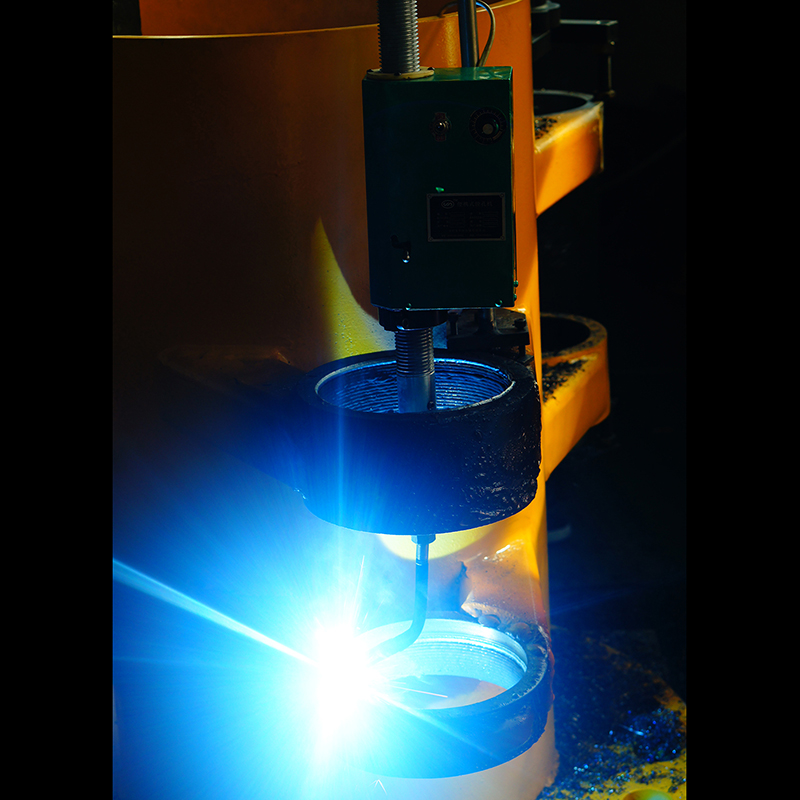

With a diameter of 3.1m, CREC 1206 was used to excavate two pump rooms with the depth of 5.5m to drain the waste water in the main tunnel of Wangjingxi Station-Yongshiying Station section of Beijing Metro Line 17. The geology is mainly soft ground consisting of silty clay, silt, fine sand, partial clay, coarse sand, etc. Od Mount Flange Facer

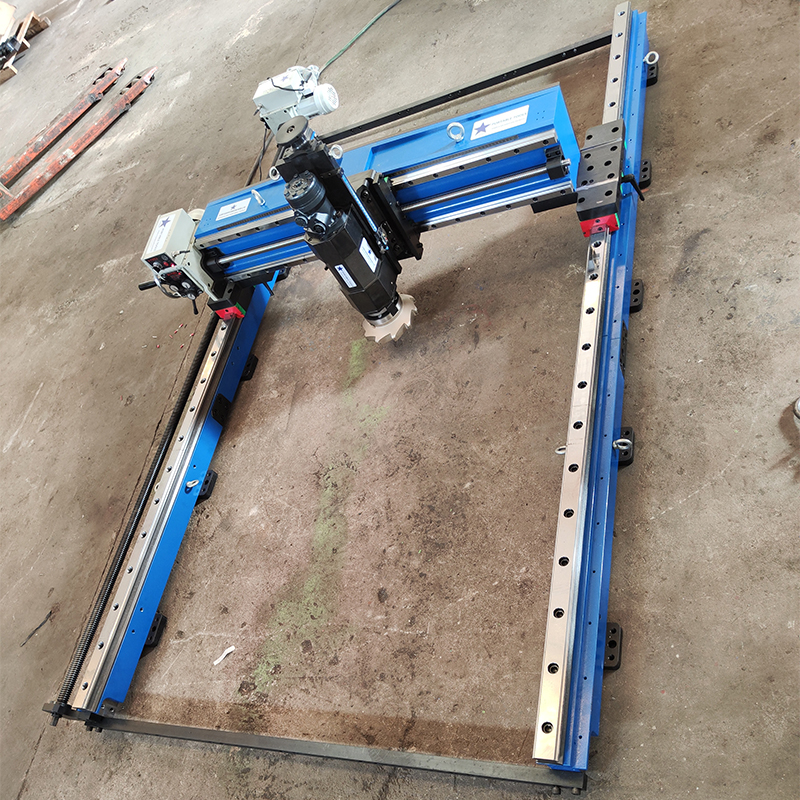

Facing various technical challenges brought by mechanized construction such as launching in an existing tunnel, main machine withdrawing and receiving, and shaft floor grouting, CREG innovatively designed a slurry-type shaft boring machine with a launch and receiving system in the existing tunnel, a double-shell shield, a retractable cutterhead and a shaft floor grouting system under pressure, realizing the integrated construction of blind shaft portal break, excavation, steel segment lining, shaft floor grouting and main machine withdrawing and receiving, which lays a solid foundation for the safe and efficient mechanized construction of a blind shaft.

It was launched on Feb. 10, 2023, and completed the excavation of first blind shaft within seven days. Moreover, the shaft floor grouting achieved its desired expectation, and the main machine was withdrawn successfully.

This project marks a new historical breakthrough in the mechanized construction of underground space, and provides an entirely new solution for T-connected tunnel construction.

RELATED: CREG Φ14.29m Dual Mode TBM Ready for Guifeng Mountain Tunnel

You must be logged in to post a comment.

Portable Facing Tools This site uses Akismet to reduce spam. Learn how your comment data is processed.