New surface filtration media are providing significantly improved flow and efficiency in sewage treatment plants. Filtration+Separation looks the use of Optimised Dutch Weaves for these demanding applications.

Increasing requirements on capacity and cleaning performance, as well as cost and energy efficiency, are characteristics of the situation currently found in sewage treatment plants worldwide. The result is a growing demand for mechanical wastewater cleaning. The standard filter devices used for this application are disc filters. The reliable separation of ultrafine particles is an absolute pre-requisite for trouble-free operation, whether for downstream filtration of raw sewage, treatment of circulating water or process water for the industry or during the production of drinking water for pre-filtration prior to membrane separation. Operating companies and plant manufacturers face ever-increasing challenges concerning the size of the particles to be separated and the residual solids content. Many applications require filtration rates up to 10 μm. German company Gebr. Kufferath AG (GKD) has developed the Optimised Dutch Weaves (ODW) for these demanding applications. These surface filtration media can significantly improve flow quality and efficiency of sewage treatment plants. Cleanable Pleated Filters

Mechanical wastewater treatment with filtration of ultrafine particles - also referred to as micro-screening - helps to significantly improve the flow quality of sewage plants. As a result, downstream ultrafiltration systems, for instance, remain virtually free of solids and the clarified wastewater can be used without further treatment to irrigate fields or parks. The disc filters applied provide quick and efficient cleaning, even of very large amounts of wastewater. They are continuously running and feature integrated backwashing. The typical characteristic of the dirt particles in these applications - to form a compressible filter cake - is a particular challenge for the filter systems. Applying increased pressures is therefore practically impossible in this filtration. GKD adds that the ‘driving force’ of the filtration is therefore only the hydrostatic pressure within the systems, resulting in low energy availability. Due to the limited filter surface, filter media combining the necessary fineness of up to 10 μm with high throughput rates and long service life are in demand to reach the required throughput. At the same time, they must be easy to clean and be free from clogging. Regular backwashing requires a permanent mechanical strength of the filter medium. However, clearly defined separation limits are crucial for its success. According to GKD, in practice it not all filter media available on the market meet this requirement, especially in the area of ultrafine filtration < 50 μm.

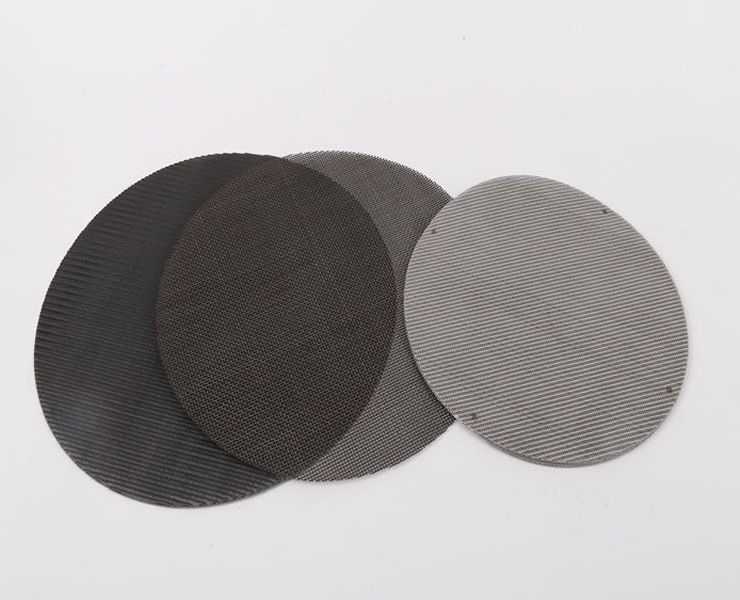

Optimised Dutch Weaves are claimed to meet all these requirements and are therefore used on a variety of disc filters in wastewater filtration. GKD says that their high performance is based on the special design of the stainless steel mesh. The slot-shaped pore geometries on the surface of the mesh are smaller than the pores inside the mesh, thus particles of the required separation limit are fully separated. In contrast, smaller particles pass through the larger interior pores without any problem and clogging. This is ensured by the good dirt holding capacity of the Optimised Dutch Weaves. GKD adds that the applied weaving technology ensures that the specific mesh geometry can be precisely reproduced at any time. As a result, the expectations on separation limits and effect in micro-screening are permanently met. This precision concerning retention level and pore geometry, as well as the low blocking tendency, make the Optimised Dutch Weaves good in micro-screening, even in comparison to plastic meshes. The particles separated on the surface can be easily removed during the regeneration cycle, thus ensuring long, trouble-free operation of the disc filter. The throughput rate and dirt holding capacity of the Optimised Dutch Weaves are also claimed to be considerably higher than on other filter media as fine as these weaves. According to GKD, this high permeability is the pre-requisite for economically feasible filter devices for the respective filter surfaces. In addition to corrosion resistance, the mesh construction made of stainless steel 1.4404 guarantees a mechanical strength that is not reached by filter media with comparable throughput rates. Filter covers made of Optimised Dutch Weaves are more reliable, efficient and accurate than plastic meshes, even when used in long-term operations.

Herringbone weave wire mesh Free access to this content is for qualifying individuals only. Corporate and institutional access requires an appropriate license or subscription. For more information contact institutions@markallengroup.com