The injection mold tooling automation specialist will preview its new Servo Mold Control system and servo-electric linear actuators at Fakuma in October.

Injection mold tooling automation specialist Servomold reports that it will introduce a new generation of control units for servo drives and a newly developed series of actuators for the execution of linear movements at the Fakuma trade show in Friedrichshafen, Germany, in October. Motor Operated Valve Actuator

Starting next year, the new SMC (Servo Mold Control) system will replace the complete universal and rack control systems that have been installed in more than 700 units since 2012. The upgrades will be available in four versions in 2024, all of which will feature intuitive operation through a uniform touch panel and automatic switching between different encoder systems.

The SMC Mini will be limited to one drive controller, the SMC Standard will be able to control up to four servo drives, and the SMC Rack version can accomodate eight drives. A combination unit has been developed in collaboration with Feller Engineering as a plug-in device for Feller's rack. In this configuration, up to five servo drives and 60 hot-runner zones can be controlled via the SMC control panel.

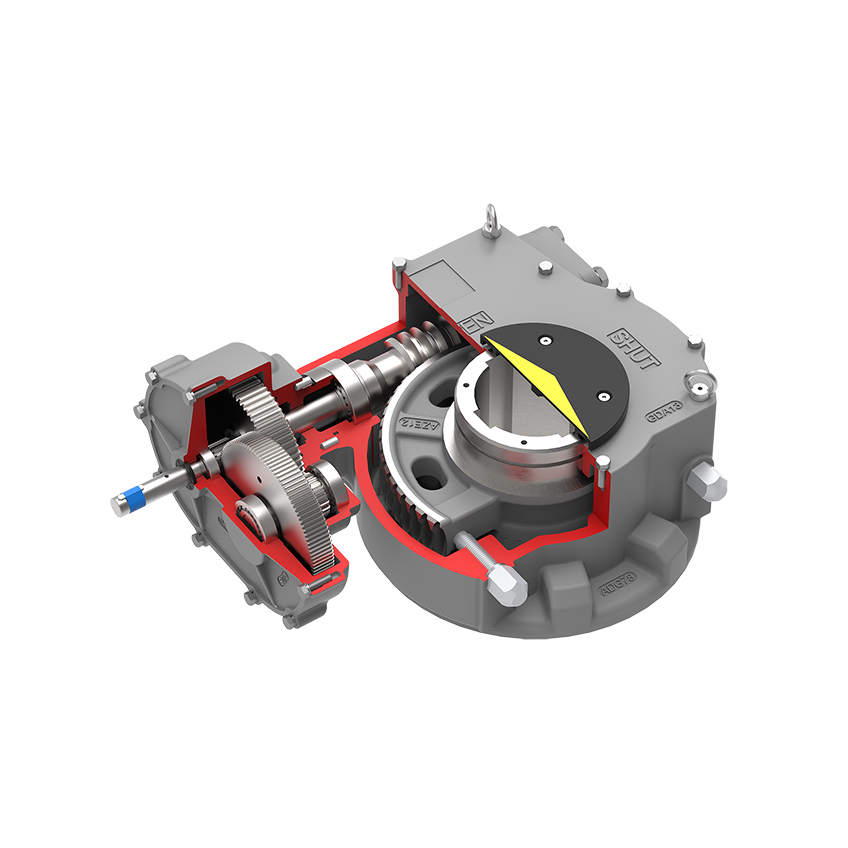

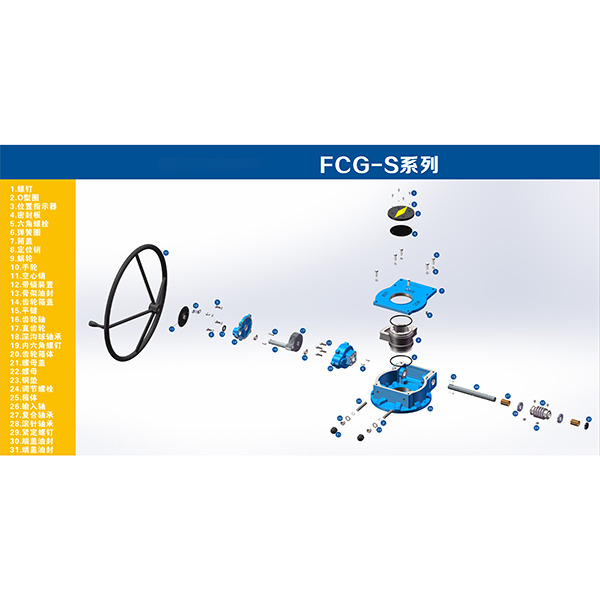

At its stand, Servomold also will introduce compact, powerful, and clean alternatives to hydraulic and pneumatic cylinders — typically used to perform translational slide, core, or platen movements in injection molds. The new SLK, SLR, and SSK servo-electric linear actuators are suitable for stroke lengths exceeding 1000 mm and offer a high nominal thrust force thanks to an integrated gear stage. By enabling the use of different spindle systems as well as individually configurable servo motors, they ensure maximum flexibility, said Servomold. The SLK is a compact version with a ball screw, the SLR is a high-performance actuator with a roller screw, and the SSK has a servo worm actuator ball screw, which has a particularly compact and flat design thanks to the 90° arrangement of the drive unit.

Servomold added in its news release that it will provide Fakuma attendees with detailed information about its application-specific solutions and entire portfolio of cost-effective, standardized servo system components. In addition to servo-electric unscrewing units and worm-drive units for unscrewing threads, the company located in Erbach, Germany, will showcase shop-ready complete unscrewing halves; high-performance servo-drive units and linear actuators; space-saving index plate turners; threaded core sets; and rotating thread core cooling systems for unscrewing units.

Servomold will exhibit in booth A2-2111 in hall A2 at the Fakuma international trade fair for plastics processing, which returns to Friedrichshafen, Germany, on Oct. 17 to 21, 2023.

Editor in chief of PlasticsToday since 2015, Norbert Sparrow has more than 30 years of editorial experience in business-to-business media. He studied journalism at the Centre Universitaire d'Etudes du Journalisme in Strasbourg, France, where he earned a master's degree. Reach him at [email protected].

Rotomolded Acetal Fuel Tanks Viable Alternatives to Fluorinated HDPE Tanks

New CEO at Diversified Plastics

Marelli Launches Lightweight, Sustainable Headlights at CES 2024

Plastic Pellet Spill in Spain Galvanizes EU Parliament

Multi Turn Valve Actuator Copyright © 2024 All rights reserved. Informa Markets, a trading division of Informa PLC.