Expertfold 50 l 80 l 110 designed to help packaging printers, converters

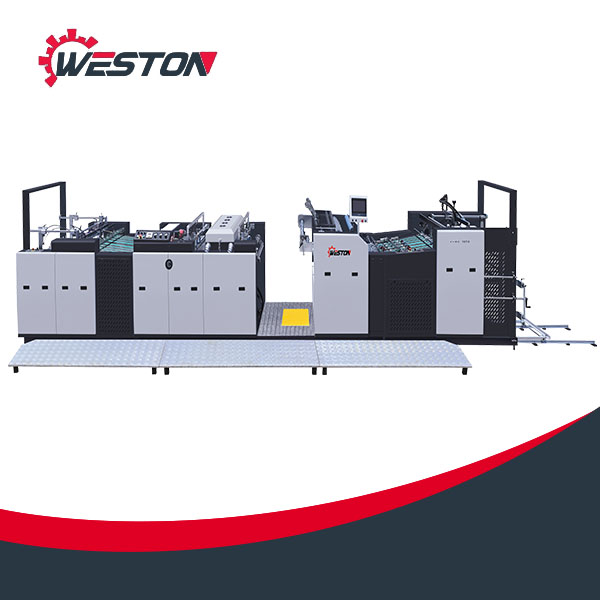

Bobst, a global manufacturer of print and packaging technologies, on 20 January announced the latest iteration of its folder-gluer for the folding carton market – the Expertfold 50 l 80 l 110. The new evolution of the machine, said to be one of the most popular in the Bobst line-up, is designed to help packaging printers and converters accomplish more in today’s rapid and resource-intensive converting market, the company announced. 4colors Screen Printing Machine

The new generation Expertfold comes equipped with a host of new features to this highly modular and extremely versatile folder-gluer, which delivers a number of box styles at speeds of up to 450m per minute. According to the company, from Accubraille to Accucheck, Speedwave, and Gyrobox, the machine can be adapted to the most complex needs. It offers the possibility to add matching peripherals allowing converters to create a complete, high-performance folding-gluing line.

To continually improve its equipment, Bobstrecently introduced the A3 version of the Expertfold, enabling a reduction in changeover times from crash-lock bottom to 4&6-corner boxes by up to 80%. The company says the objective of the new version was to enhance this all-rounder, increase productivity and move closer towards Bobst’s vision of a fully digitized and connected converting process with maximum automation and sustainability.

With new designs and adaptations, the ergonomics of the Expertfold have been improved and the machine footprint cut down. Specially designed security doors allow easy access to the 4&6-corner module. The leaner design provides maximum safety and frees up space at the back of the machine. The handles on the upper conveyors have been redesigned, adding further precision and stability to the positioning of the equipment. Plus, the machine now features pneumatic feeder ramps, reducing the workload for operators and cutting down machine setup time by 20%, the company says.

“ The evolution of our Expertfold is another example of how we want to offer converters the most performant and ergonomic machines,” says Pierre Binggeli, head of Product Line Folder-gluers at Bobst. Apart from the obvious advantages for the operators, clever ergonomics can help to reduce setup times and increase the precision of the machine settings. “With the most recent changes, we managed to cut down setup time and improve both productivity and box quality even further – because converters need to be agile and deliver zero-fault products. At the same time, user-friendliness and practicality play an important part in creating a sustainable work environment,” Binggeli says.

The integration of the Bobst machine-control sphere followed the same reasoning. Like the current platform, it offers the possibility to retrieve repeat jobs, control the machine functions, and provides access to the Bobst Connect Essential package, which was launched last year. This end-to-end digital solution already enables companies to drive productivity by accessing accurate performance data, progress indicators, and reporting. It also ensures high-priority remote assistance.

However, Sphere has been designed to include a whole range of other functions, which will be part of the Bobst Connect platform, enabling efficient data flow between physical equipment and digital solutions for rapid, transparent communication throughout the supply chain, optimizing the entire production workflow.

Pierre Binggeli says: “Our Expertfold line has an extremely strong reputation as one of the most trusted and high-performance in-line folder-gluers on the market. Naturally, as we continue to evolve our product line in response to developing market needs, we are continually adding new functionality and our new iteration is a perfect example. Each individual change is implemented because of real benefits to our converting customers, whether it’s faster setup and changeover or the possibility of accelerating the transition to Industry 4.0. This is what innovation is about: continually thinking about how to improve even the best of products.”

The impact, resilience, and growth of responsible packaging in a wide region are daily chronicled by Packaging South Asia.

A multi-channel B2B publication and digital platform such as Packaging South Asia is always aware of the prospect of new beginnings and renewal. Its 16-year-old print monthly, based in New Delhi, India has demonstrated its commitment to progress and growth. The Indian and Asian packaging industries have shown resilience in the face of ongoing challenges over the past three years.

As we present our publishing plan for 2023, India’s real GDP growth for the financial year ending 31 March 2023 will reach 6.3%. Packaging industry growth has exceeded GDP growth even when allowing for inflation in the past three years.

The capacity for flexible film manufacturing in India increased by 33% over the past three years. With orders in place, we expect another 33% capacity addition from 2023 to 2025. Capacities in monocartons, corrugation, aseptic liquid packaging, and labels have grown similarly. The numbers are positive for most of the economies in the region – our platform increasingly reaches and influences these.

Even given the disruptions of supply chains, raw material prices, and the challenge of responsible and sustainable packaging, packaging in all its creative forms and purposes has significant headroom to grow in India and Asia. Our context and coverage engulf the entire packaging supply chain – from concept to shelf and further – to waste collection and recycling. We target brand owners, product managers, raw material suppliers, packaging designers and converters, and recyclers.

In an admittedly fragmented and textured terrain, this is the right time to plan your participation and marketing support communication – in our impactful and highly targeted business platform. Tell us what you need. Speak and write to our editorial and advertising teams! For advertisement ads1@ippgroup.in , for editorial info@ippgroup.in and for subscriptions subscription@ippgroup.in

Check your inbox or spam folder to confirm your subscription.

What lies in store for the packaging industry in India and South Asia this coming year? Inflation, disruption of supply chains or environmental regulation? Or the resumption of high rural demand, continued investment and industry consolidation? Whatever happens, Packaging South Asia will be there, providing clarity and independent technical and business information in India and South Asia and around the world. We are a compact Indian organization bringing a window of fair and rigorous technical and business information that the industry can access this year and beyond. Please support us with your advertising and subscriptions, to keep us going and growing.

Check your inbox or spam folder to confirm your subscription.

Screen Printing Machine Save my name, email, and website in this browser for the next time I comment.