On June 30, 2020, Insteel Industries Inc., Mid-South Wire Company, National Wire LLC, Oklahoma Steel &Wire Co., and Wire Mesh Corp. (“Petitioners”), filed a petition for the imposition of antidumping and countervailing duties on standard steel welded wire mesh from Mexico.

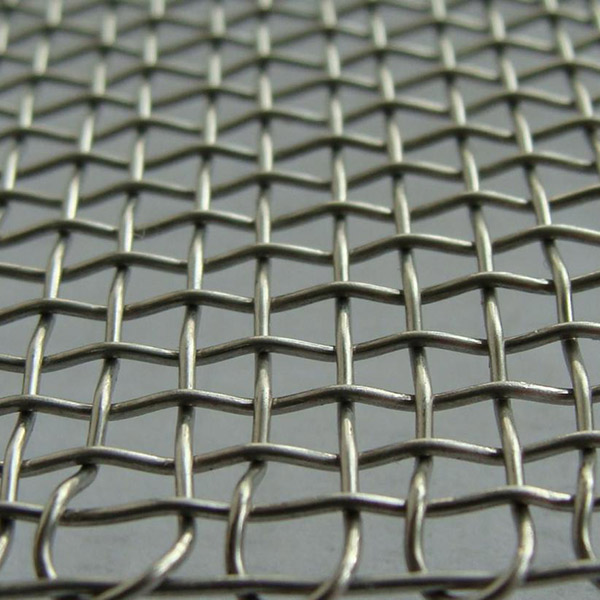

The scope of this investigation covers uncoated standard welded steel reinforcement wire mesh (“Standard Welded Wire Mesh”) produced from smooth or deformed wire. Subject Standard Welded Wire Mesh is produced in square and rectangular grids of uniformly spaced steel wires that are welded at all intersections. Sizes are specified by combining the spacing of the wires in inches or millimeters and the wire cross-sectional area in hundredths of square inch or millimeters squared. Subject standard welded wire mesh may be packaged and sold in rolls or in sheets. 316 Stainless Steel Mesh

Subject standard welded wire mesh is currently produced to ASTM specification A1064/A1064M, which covers carbon-steel wire and welded wire reinforcement, smooth and deformed, for concrete in the following seven styles:

The first number in the style denotes the spacing between the longitudinal wires and the second number denotes the spacing between the transverse wires. In the first style listed above, for example, “6X6” denotes a grid size of six inches by six inches. “W” denotes the use of smooth wire, and “D” denotes the use of deformed wire in making the mesh. The number following the W or D denotes the cross-sectional area of the transverse and longitudinal wires in hundredths of a square inch (i.e., W1.4 or D1.4 is .014 square inches).

Smooth wire is wire that has a uniform cross-sectional diameter throughout the length of the wire. Deformed wire is wire with indentations or raised transverse ribs, which results in wire that does not have a uniform cross-sectional diameter throughout the length of the wire.

Rolls of Subject standard welded wire mesh are currently produced in the following styles and actual width and length combinations:

Style: 6X6 W1.4/W1.4 or D1.4/D1.4 (i.e., 10 gauge)

Style: 6X6 W2.1/W2.1 or D2.1/D2.1 (i.e., 8 gauge)

Style: 6X6 W2.9/W2.9 or D2.9/D2.9 (i.e., 6 gauge)

All rolled standard welded wire mesh is included in scope regardless of length.

Sheets of subject standard welded wire mesh are currently produced in the following styles and actual width and length combinations:

Style: 6X6 W1.4/W1.4 or D1.4/D1.4 (i.e., 10 gauge)

Style: 6X6 W2.1/W2.1 or D2.1/D2.1 (i.e., 8 gauge)

Style: 6X6 W2.9/W2.9 or D2.9/D2.9 (i.e., 6 gauge)

Style: 6X12 W4/W4 or D4/D4 (i.e., 4 gauge)

Style: 4X4 W2.9/W2.9 or D2.9/D2.9 (i.e., 6 gauge)

Style: 4X4 W4/W4 or D4/D4 (ie, 4 gauge)

Any product imported, sold, or invoiced in one of these size combinations is within the scope.

ASTM specification A1064/A1064M provides for permissible variations in wire gauges, the spacing between transverse and longitudinal wires, and the length and width combinations. To the extent a roll or sheet of welded wire mesh falls within these permissible variations, it is within this scope.

ASTM specification A1064/A1064M also defines permissible oversteeling, which is the use of a heavier gauge wire with a larger cross-sectional area than nominally specified. It also permits a wire diameter tolerance of ±0.003 inches for products up to W5/D5 and ±0.004 for sizes over W5/D5. A producer may oversteel by increasing smooth or deformed wire diameter up to two whole number size increments on Table 1 of A1064. Subject standard welded wire mesh has the following wire diameter ranges, which account for both oversteeling and diameter tolerance:

To the extent a roll or sheet of welded wire mesh falls within the permissible variations provided above, it is within this scope.

In addition to the tolerances permitted in ASTM specification A1064/A1064M, Standard welded wire mesh within this scope includes combinations where:

Length is measured from the ends of any wire and width is measured between the center-line of end longitudinal wires. Additionally, although the subject Standard welded wire mesh typically meets ASTM A1064/A1064M, the failure to include certifications, test reports or other documentation establishing that the product meets this specification does not remove the product from the scope. Standard welded wire mesh made to comparable foreign specifications (e.g., DIN, JIS, etc.) or proprietary specifications is included in the scope.

Excluded from the scope is wire mesh that is galvanized (i.e., coated with zinc) or coated with an epoxy coating. In order to be excluded as galvanized, the excluded welded wire mesh must have a zinc coating thickness meeting the requirements of ASTM specification A641/A641M. Epoxy coating is a mix of epoxy resin and hardener that can be applied to the surface of steel wire. Merchandise subject to this investigation is classified under HTSUS categories 7314.20.0000 and 7314.39.0000. While HTSUS subheadings are provided for convenience and Customs purposes, the written description of the scope of this investigation is dispositive.

Website: http://www.insteel.com/

Contact: H.O. Woltz III, President and CEO

Website: https://www.midsouthwire.com/

Contact: John T. Johnson, Jr., Owner and President

Contact: Alejandra Abbott, Vice President

Oklahoma Steel & Wire Co.

Contact: Lou Richards, Vice President of Sales

KELLEY DRYE & WARREN LLP

For a list of foreign producers/exporters alleged by Petitioner, please see Attachment I

For a list of importers alleged by Petitioner, please see Attachment II

For a list of alleged countervailing duty programs, please see Attachment III .

DISCLAIMER: Because of the generality of this update, the information provided herein may not be applicable in all situations and should not be acted upon without specific legal advice based on particular situations.

© Husch Blackwell LLP | Attorney Advertising

Wire Net For Windows Copyright © JD Supra, LLC