Secure .mil websites use HTTPS

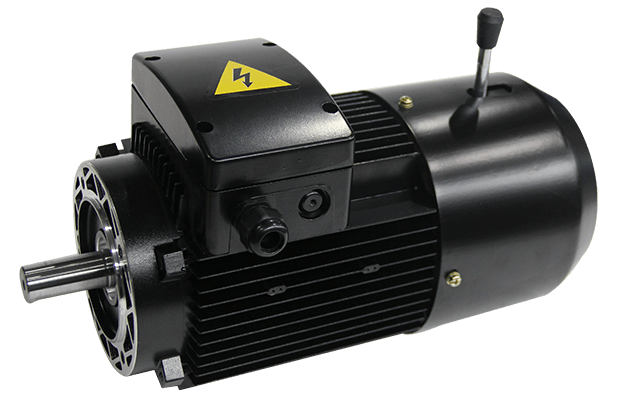

Please be Patient, Site Under Construction Inverter Starter Motor

Fabric Worker: (75F) A fabric worker plans, designs, lays out, constructs and installs containments of various sizes and configurations for radiological, environmental and cleanliness controls shipboard, in dry-docks and in facilities. Other work can include reupholstering ship’s furnishings, manufacturing tool bags, protective coverings, and other items on request. Materials used include polyvinyl chloride (PVC) and polyurethane (PI-JR) sheeting, herculite, Kevlar, canvas, naugahyde, linen and other flexible materials.

Insulator: (57I) An insulator applies a variety of insulation materials on hulls, steam turbines, distillation plants, refrigeration plants, ventilation ducts and other piping systems and equipment to prevent loss of heat or cold, prevent condensation and reduce noise levels aboard ship and noise transfer to the sea. Materials used include molded calcium silicate, fiberglass and foam plastic insulations along with insulating and adhesive cements.

Painter-Blaster: (71P) A painter-blaster prepares surfaces and applies coatings on interior and exterior surfaces, tanks and voids aboard ships and as shop applications to meet specific preservation requirements. Duties include abrasive blasting, needle gunning and sanding surfaces for preparation. Also included is applying coatings such as alkyds, epoxies and powder coatings by brushing, rolling and spraying.

Plastic Fabricator: (76P) A plastic fabricator builds, modifies and repairs plastic, fiberglass and rubber components using techniques such as casting, laminating, thermoforming , vacuum bag molding, compression molding and spray coating. Duties may also include working with terrazzo, vinyl floor coverings, sound damping, Special Hull Treatment, wood, Plexiglas, powder coatings and plastisol.

Shipwright: (64S) A shipwright’s duties include erecting, maintaining and removing scaffolding in both nuclear and non-nuclear applications. Woodworking duties will include building temporary enclosures, plenums, shipping skids, mock-ups and pipe templates. A shipwright will also use optical instruments to provide reference points and alignment services during docking evolutions and overhauls.

Crane Operator: (742) Operates portal and mobile cranes to install or remove ship’s components. Works with rigging crews to navigate lifts through confined spaces where maneuverability is restricted and accuracy is critical. Operates bridge cranes to lift, transport and position materials in confined shop areas.

Heavy Mobile Equipment Mechanic: (98M) A heavy mobile equipment mechanic performs maintenance and repair on various types of heavy-duty equipment such as floating, portal, gantry, bridge and truck cranes. Duties may also include work on railroad locomotives. Work may include repair of diesel and gasoline engines gearboxes, power transfer and braking systems and DC generators.

Heavy Mobile Equipment Servicers: (742) Cleans, replenishes supplies and performs minor maintenance such as fueling and lubrication on portal and mobile cranes, and locomotives. Performs crane rail maintenance and ensures path is clear of obstructions. Assists crane operator during crane operations as a track walker and by acquiring material.

Rigger: (72R) A Rigger selects, installs, and uses cables, ropes, shackles, beam clamps, strongbacks and other weight handling gear to lift, move, and position heavy loads. Riggers use complex multipoint suspension techniques to maneuver over, under, and around obstacles by tilting, dipping and turning the suspended load. Other duties include the fabrication, installation and repair of standing and running rigging and wire cable or fiber rope articles such as slings, towing bridles, wire rope nets, and other ship and boat rigging and weight handling gear. Riggers direct the operation of cranes and similar equipment and plan for clearance and safety factors. They assist in ship docking operations by laying out and handling docking lines and tackles, snubbing lines on cleats or bollards, hauling in lines by operating capstans, and performing similar duties. Riggers work with Shipwrights for dock build-ups and for the positioning of the ship during docking operations.

Electrician: An electrician may perform duties in 1 of 3 areas, marine, production, or services.

Marine Electrician: (51E) A marine electrician installs, repairs, manufactures and tests nuclear and nonnuclear shipboard electrical systems and control equipment. Typical work includes removing and reinstalling equipment, repairing and replacing cabling, and testing rotating equipment, motor control equipment, switchboards, power panels, circuit breakers, connectors, communication equipment, batteries, lighting and cabling. Work is performed in shop and onboard the submarine.

Production Machinery Electrician: (06E) A production machinery electrician maintains, installs, repairs, retrofits and troubleshoots electrical circuits and components associated with industrial machinery. This includes the performance of electrical preventive maintenance.

Service Electrician: (99E) A service electrician provides temporary electrical distribution services to U.S. Navy vessels during overhaul I repair operations. Typical duties may include installing and connecting temporary shore power to lighting, ships systems support equipment and alarm systems.

Electronic Industrial Controls Mechanic: (06E) An electronic industrial controls mechanic repairs, tests and calibrates electronic measuring equipment. Duties may also include maintenance and repair of CNC systems, automatic welding equipment, automated access control systems, security and alarm systems and fiber optic closed circuit systems.

Electronic Industrial Controls Mechanic (Cranes): (98X) An electronic industrial controls mechanic for cranes troubleshoots, repairs, adjusts, modifies, and tests electronic controls on lifting and handling equipment. This includes solid-state motor and generator controls, computer-controlled hoist motor drives, radio-controlled components, monitoring and alarm systems, and indication equipment. Duties also include the duties of the crane electrician.

Electronics Mechanic: An electronics mechanic installs, troubleshoots, repairs and tests shipboard electronic equipment and systems. Duties of the electronics mechanic include continuity and insulation resistance checks of cabling, the testing and troubleshooting of various circuit card components, transducers and hydrophones, manufacturing and repair of fiber optic cables and components, including optical loss and return loss testing. An electronic mechanic also tests sonar, fire control, communications and navigation systems. Work is performed in shop and onboard the submarine.

Sheet-metal Mechanic: (17T) A sheet-metal mechanic fabricates, modifies, repairs, assembles, and installs sheet metal items in buildings and aboard U.S. Navy vessels. Sheet metal items may include HVAC duct, lockers, protective covers, and metal or plastic laminate paneling. Duties also include the removal and reinstallation of bulkheads, galley equipment, and berthing areas on U.S. Naval vessels.

Shipfitter: (11S) A shipfitter plans, manufactures, installs, removes, and repairs structural assembles aboard U.S. Navy vessels. These assemblies vary in size from less than 100 pounds to over several tons and consist of ferrous or non-ferrous metals.

Welder: (26W) A welder cuts and joins all types of industrial and marine metals aboard U.S. Navy vessels and in facility buildings using complex welding and thermal cutting processes.

Shipfitter Lofter: (11S2) A shipfitter lofter converts engineering designs, offsets and other design criteria into 3D models, templates, shapes and Computer Numerical Control (CNC) programs, for the fabrication of structural components. Duties also include performing 3D coordinate measurement and alignment using a variety of Coordinate Measuring Machines (CMM) and providing reports of data to applicable tech codes.

Non-Destructive Tester: (35M) A non-destructive tester (metals inspector) identifies physical and mechanical properties or defects of a piece of material or structure without altering its end use capabilities. This demanding and ever-changing field requires continuous academic study. The inspection methods used in the Naval Ship repair industry can be classified to the following groups: Visual, Liquid Penetrates, Magnetic Particle, Ultrasonic, Radiographic and Eddy Current.

Air Conditioning Equipment Mechanic: (56A) An Air Conditioning Equipment Mechanic removes, repairs, overhauls, aligns, installs, tests, and adjusts ship’s air conditioning and refrigeration systems and components including compressors, pumps, valves, heat exchangers, switches, electrical and pneumatic system controls. Removes and replaces various types of refrigerants, and conducts pressure, vacuum, and operational testing of air conditioning and refrigeration systems using nitrogen and refrigerants.

Machinist: (31M) A machinist manufactures new and repairs existing parts using lathes, milling machines, boring mills, drills and CNC operated equipment. Duties may include disassembling, inspecting, reassembling and testing components such as turbines, valves, pumps and compressors. Duties may also include machining of forged and heat-treated material as well as rubber and plastics.

Marine Machinery Mechanic: (38M) A marine machinery mechanic installs, removes, optically aligns, tests, overhauls and repairs ship’s main propulsion machinery including turbine generators, internal combustion engines, reduction gears, propeller shafts, pumps, valves, auxiliary engines, nuclear reactor components, ordnance machinery and other shipboard components. Duties may also include work on hydraulic actuators, boat davits, capstans, windlasses and auxiliary cranes.

Production Machinery Mechanic: (06M) A production machinery mechanic installs, repairs, inspects, aligns, analyzes and rebuilds industrial plant equipment and machinery. This process includes operating and maintaining ultra-high-pressure water jetting and high-pressure air systems as well as maintaining, inspecting and rebuilding nuclear support equipment facilities.

Shipboard Pipefitter: (56P) A shipboard pipefitter removes, repairs, manufactures, installs and tests piping systems aboard U.S. Navy vessels. Typical duties may include using piping diagrams to determine angles of bends, using machinery to bend those angles and installing the piping aboard ship. Materials used may include copper, nickel copper and stainless steel.

Temporary Services Pipefitter: (99P) A temporary services pipefitter installs, tests, maintains and removes temporary services to U.S. Navy vessels during overhaul I repair operations. Temporary services provided may include HVAC, air and water for various uses, effluent discharge and steam.

Industrial Equipment Mechanic: (99D) A industrial equipment mechanic operates and performs emergency breakdown, planning and preventative maintenance and repairs on Pore Water systems, High Pressure Systems, dry dock pump wells, caissons, capstans, operations and maintenance of equipment to include but not limited to, pumps, motors. valves, controls, piping and compressors.

Crane Duty Motor Commander Naval Sea Systems Command 1333 Isaac Hull Avenue, SE Washington Navy Yard, DC 20376 202-781-0000