Machine Learning is capable of upgrading FDM 3D printed parts to such a level that they overtake their injection moulded counterparts, suggests a study by Exponential Technologies.

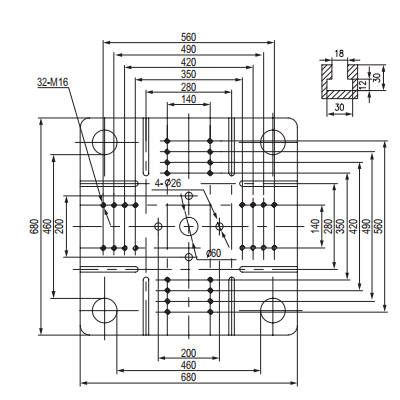

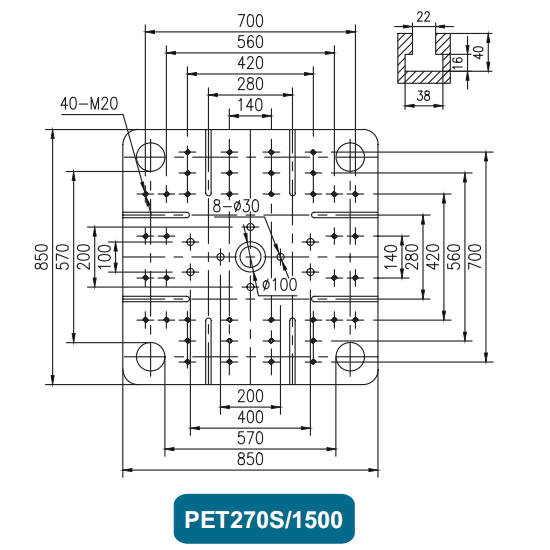

In partnership with Orion-AM, a 3D printer manufacturer based in Berlin, Germany, Exponential Technologies developed 3D printer settings using its Data Science Platform, xT SAAM, that used machine learning in order to achieve the superior mechanical properties. Injection Molding Press

Orion-AM’s new A150 Series 3D printer combines the traditional layer-by-layer process of FDM with thermal radiation heating, all managed within a temperature controlled build chamber.

With data fed into the xT SAAM platform from each PEEK filament test part, Orion-AM varied extruder temperature, layer temperature, fan speed, bed temperature, and infill overlap using suggestions from the machine learning system.

According to the study, which produced between 20 to 30 printed samples with materials from Solvay and Evonik, results improved with each additional sample. Orion-AM concluded the experiment with results that exceeded injection moulding in both tensile strength and elastic modulus.

For comparison, the tensile strength of injection molded PEEK is around 90MPa and the elastic modulus is around 3.3GPa. Orion-AM was able to obtain 95MPa tensile strength and 3.8GPa tensile modulus for Solvay’s PEEK filament utilizing xT SAAM, while Evonik’s PEEK filament for industrial grade achieved 92.8MPa tensile strength and 3.7GPa tensile modulus.

“Using the xT-SAAM platform, we were able to fine tune our 3D printing process to achieve a tensile strength and elastic modulus for PEEK that exceeded injection molding in Z-orientation in as little as 30 samples,” said Orion-AM CEO Adam Rumjahn

You must be logged in to post a comment.

Newsletter • FREE digital magazine • print magazine

Molding Clamp © 2008-2022 X3DMedia 19 Leyden Street. London, E1 7LE, UK Tel: +44(0)20 3355 7310